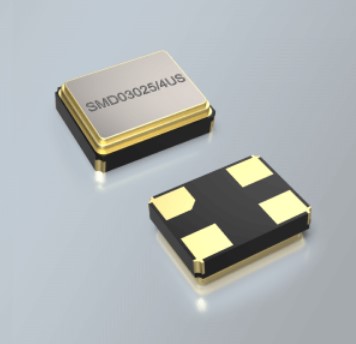

PETERMANN贴片石英SMD03025/4US 26.000MHz10/10/0+70/12pF适用于超声波低成本应用

每个开发和生产专家都知道这一点!石英晶体不能处理超声波焊接和清洗。高频焊接或清洗过程会损坏石英晶体谐振器。

来自德国兰兹伯格的钟表专家PETERMANN-TECHNIK是世界上第一家推出小型化SMD石英腕表的公司尺寸为3.2×2.5毫米的陶瓷外壳,它是专门为处理基于超声波的焊接和清洗而开发的。轰动!

与此同时,采用3.2×2.5mm/4pad外壳的SMD石英(系列SMD03025/4)已成为采用陶瓷外壳的最便宜的小型化SMD石英。因此,适合超声波焊接和清洗的石英在需求量最大的外壳(3.2×2.5mm/4pad)贴片晶振中提供是合乎逻辑的。

适用于超声波的贴片石英美国标准“系列可以通过超声波焊接和清洗。为此,该石英谐振器具有特殊的固定超声波限值,设计用于15KHz、20KHz、35KHz和40KHz的超声波频率。

“SMD03025/4US”石英晶体的频率范围为12–40MHz,在+25°C温度下的频率容差起始值为10ppm,在-20/+70°C温度范围外的温度稳定性起始值为10ppm .在-40/+85°C工业温度范围外,最接近的温度稳定性为15ppm。

由于价格非常实惠,可以使用在洁净室中制造的抗超声波全能仪器在任何应用中这要求非常便宜的SMD石英具有出色的参数和出色的耐用性,例如在汽车、医疗、嵌入式、工业、商业、WIFI、无线(WLAN、ISM、KNX、ZigBee、Z-Wave等领域。)、消费和电信行业等。

当然,彼得曼技术公司的产品还包括32.768kHz解决方案(石英和超低功耗振荡器)。

除了非常广泛的产品范围,彼得曼技术公司的专家还提供全面的产品建议。根据需要,内部工程人员也可以进行非常全面的电路分析/电路仿真。这些分析是根据德国工业标准/IEC60444标准对振荡晶体进行的,包括振荡安全测试(确定准确的振荡储备)、压电性能测定和许多其他测试。

令人难以置信的广泛最终报告提供了对连接的见解,将确认测试电路的正确尺寸或可能包含调整建议。对该系列的支持是与客户的工程、采购、生产和质量保证部门协调进行的。目的是利用非常广泛的服务范围,为客户加快上市速度。

SMD03025/4US石英晶体产品特征:

+建议用于超声波塑料外壳焊接工艺

+高可靠性,低成本

+提供精密公差和稳定性

+电阻降低石英设计,实现快速安全的振荡启动

+非常适合用于电子产品、通讯设备、汽车产品、医疗设备、蓝牙、无线等。

PETERMANN贴片石英SMD03025/4US 26.000MHz10/10/0+70/12pF适用于超声波低成本应用

LOW-COST SMD QUARTZ SUITABLE FOR ULTRASONICEvery development and production specialist knows it! Quartz crystal can’t handle ultrasonic welding and cleaning. The quartz resonators are damaged by the high-frequency welding or cleaning process.

The clocking specialist PETERMANN-TECHNIK from Landsberg am Lech is the first in the world to present an SMD quartz in miniaturised ceramic housing measuring 3.2×2.5 mm, which was specially developed to handle ultrasonic-based welding and cleaning. A sensation!

In the meantime, the SMD quartz in 3.2×2.5 mm/4pad housing (series SMD03025/4) has become the cheapest miniaturised SMD quartz in ceramic housing. For this reason, it is only logical that the quartz suitable for ultrasonic welding and cleaning is available in the housing that is in greatest demand, 3.2×2.5 mm/4pad.

The SMD quartz suitable for ultrasonic from the “SMD03025/4US” series can be welded and cleaned by ultrasonic. In doing so, this quartz, whose quartz resonator has a special fixed ultrasonic limit, is designed for ultrasonic frequencies of 15 kHz, 20 kHz, 35 kHz and 40 kHz.

The “SMD03025/4US”, available with a frequency range of 12–40 MHz, can be shipped with frequency tolerances starting at ±10 ppm at +25 °C and with temperature stabilities beginning at ±10 ppm beyond the temperature range of -20/+70 °C. Beyond the industrial temperature range of -40/+85 °C, the closest temperature stability is ±15 ppm.

Because of the very affordable price, the ultrasonic-resistant all-rounder, which is manufactured in clean rooms, can be used in any application that demands very inexpensive SMD quartz with excellent parameters and outstanding durability, such as in the automotive, medical, embedded, industrial, commercial, WIFI, wireless (WLAN, ISM, KNX, ZigBee, Z-Wave, etc.), consumer and telecommunications sectors and more.

Of course, the range of PETERMANN-TECHNIK products also includes 32.768 kHz solutions (quartzes and ultra low power oscillators).

In addition to the very extensive product range, the specialists at PETERMANN-TECHNIK also provide comprehensive product advice. Very comprehensive circuit analyses/circuit simulations can also be performed by in-house engineering as needed. These analyses are carried out based on the DIN/IEC60444 standards for oscillating crystals and include oscillation safety tests (determination of the exact oscillation reserve), determination of the piezoelectricity and many other tests.

The incredibly extensive final report provides insight on the connection, will confirm the correct dimensioning of the tested circuitry or may contain proposals for adjustment. Support for this series is carried out in coordination with the customer’s engineering, purchasing, production and QA departments. The aim is to make use of a very extensive range of services to be able to facilitate a fast time to market for the customer.

“推荐阅读”

- 晶振虽小,赋能千行论丹麦格耶KX-13晶振的产业链

- IQD石英晶体LFXTAL003166REEL处理注意事项

- Euroquartz新的MEMS滤波器24.890MHzXOPL53100UCTA系列和短型滤波器目录

- Cardinal卡迪纳尔CX5Z-A1B2C5-40-24.0D18石英晶体的工作原理

- SHINSUNG的SXO-22-33ST-30F3-20.000MHz时钟振荡器型号列表

- 瑞萨RH850/C1M-Ax汽车应用和解决方案

- Raltron时钟振荡器CO2016-12.800-2.5-50-TR产品数据手册

- Microchip物联网安全挑战和解决方案DSC1123CI2-156.2500

- Golledge频率控制GSX-211在可穿戴设备和健康监测中的作用

- RENESAS推出性能卓越的RA8 MCU

【责任编辑】:精工富士版权所有:http://www.seikocrystal.com转载请注明出处

相关晶振行业

- Geyer石英晶振12.60233应用领域

- Skyworks下一代Si89xx系列有助于电动汽车更快充电

- PETERMANN贴片石英SMD03025/4US 26.000MHz10/10/0+70/12pF适用于超声波低成本应用

- PETERMANN低ESR石英SMD03025/426.000MHz10/10/0+70/12pF用于快速振荡启动

- Bliley恒温晶体振荡器剖析BOVSE-24MDBECCT

- Quantic Wenzel Frequency Synthesizer to Support NASA’s Europa Clipper

- 领先同行纳卡有源晶振专用国防设备

- 遥遥领先的Renesas Electronics关于低压电机的驱动解决方案

- 遥遥领先的Skyworks Electronics产品对不同领域的影响

- Frequency Management International

康华尔公众号

康华尔公众号